Diamond Cutting And Polishing

Billion year old creations of nature, every natural diamond endures a lot before it turns into the perfect polished masterpiece we all desire & adore. Experience a diamond journey, from a rough stone to a sparkling gem.

Natural diamonds are the ultimate symbol of strength and resilience, prized possessions either bought to commemorate a special occasion or to be passed down from one generation to the next as family heirlooms. After the long process of polishing and cutting that rough diamonds go through before reaching a jewelry store near you, it is quite fitting that natural diamonds are considered unique and precious.

Journey through Diamond Processing: Finding Rough Diamonds

The first step after the diamond mining process is comminution where the ore is crushed and milled. Once the ore is crushed, the rough diamonds are separated from the slurry by passing it over a grease belt since diamonds are attracted to grease. The natural rough diamonds are then measured and sorted before the cutting and polishing process begins.

Here are some lesser-known facts about how to polish diamonds and diamond-cut chart that you didn’t know:

1. Return On Investment In Diamond Manufacturing

Natural diamonds have inherent emotional value for its buyer but for its manufacturer, the ROI trumps everything else. Each rough diamond is carefully and thoroughly examined before a decision is made on how it is to be cut. The diamond is then marked in a way that it yields the highest value.

Based on the imperfections and the clarity it can yield, two to three diamonds can be marked from a single rough diamond.

2. Diamond Cuts

While colour, clarity and carat are the most recognizable criteria for buying a diamond, a diamond-cut chart can help you differentiate between a good diamond and a great diamond.

Seeing a diamond cut chart you’d think that the fancy-looking heart-shaped diamond would require more skill to cut and hence would be more expensive. But, the round cut diamonds command premium pricing, irrespective of a carat!

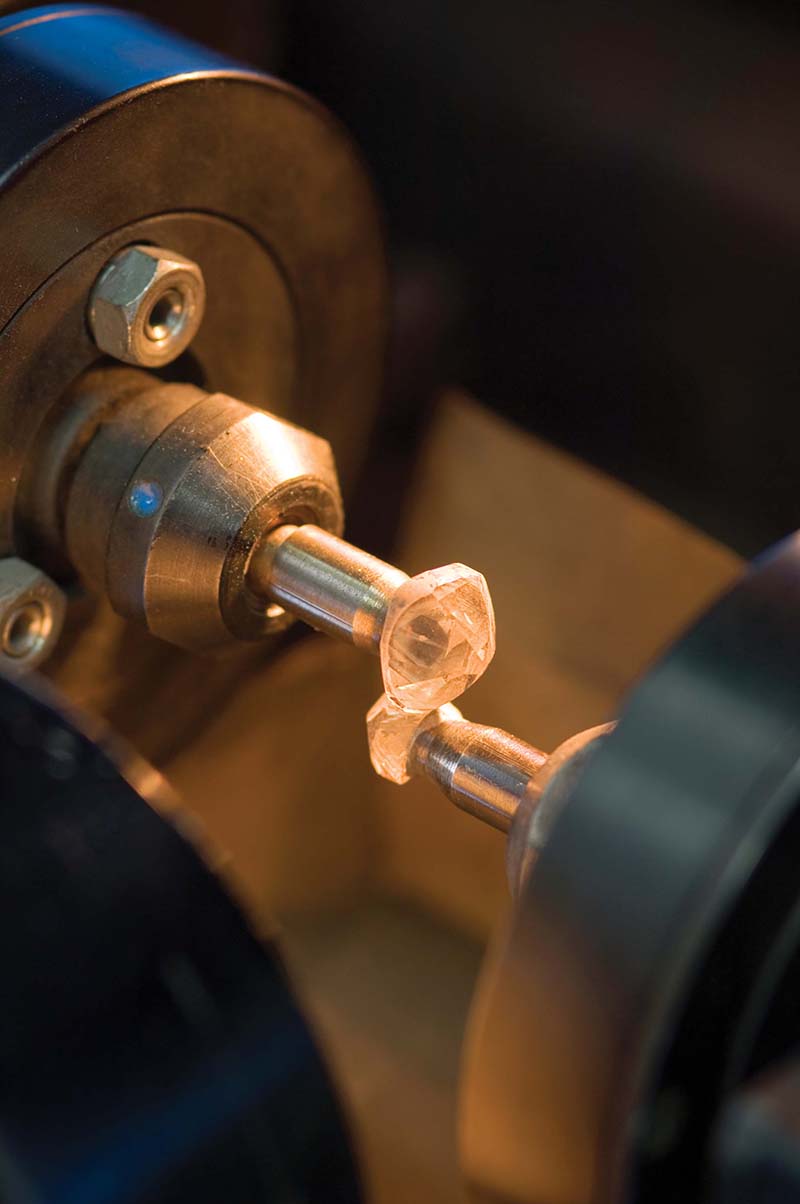

3. It Takes a Diamond to Cut Another Diamond

A specialized saw, which rotates at a speed of 4000 revolutions per minute, or laser is used to cut the rough diamond into different pieces. This process, called diamond sawing, takes 4 to 8 hours. Interestingly enough, it is not the copper saw that cuts through the natural rough diamond but the diamond dust it is coated with. Since a diamond is the hardest known mineral to man, only another diamond can cut it.

4. The Art of Polishing Diamonds

How to polish diamonds? In a process called brillianteering, the facets of the cut diamond are polished so that it reflects and refracts the optimal amount of light. It is the polishing of the natural diamond that determines how much fire, brilliance and sparkle the diamond will have.

5. All You Need is Some Olive Oil and Diamond Powder

Scaif – a diamond cutting wheel – was invented in the late fifteenth century by a diamond cutter in Antwerp called Lodewyk van Berken. The scaif revolutionized the art of diamond cutting.

The coating of oil and diamond dust ensured that the rough diamond wouldn’t shatter while cutting. Though the tools for cutting and polishing natural diamonds have become sophisticated over the years, a scaif is still used to bring out the brilliance of a diamond.

Diamond cutting and how to polish diamonds is not only an art but a science as well. Not everyone can become a diamantaire – a person specializing in diamonds. It requires years of study and attention to detail. The process has little room for errors, thus only adding to the glory and enigma of the diamond – as it completes its long journey and transforms from a natural rough diamond to a brilliant jewel.