Surat: Where The World’s Diamonds Find A Home

Whether you are a diamond connoisseur or from the jewellery trade, no conversation about the gem can be complete without the mention of Surat. For nearly a century now, Surat has been one of the nerve centres of the global diamond industry where 90 percent of the world’s natural diamonds come to life. This is where rough stones are transformed into brilliant polished diamonds and then crafted into trend-setting jewellery designs.

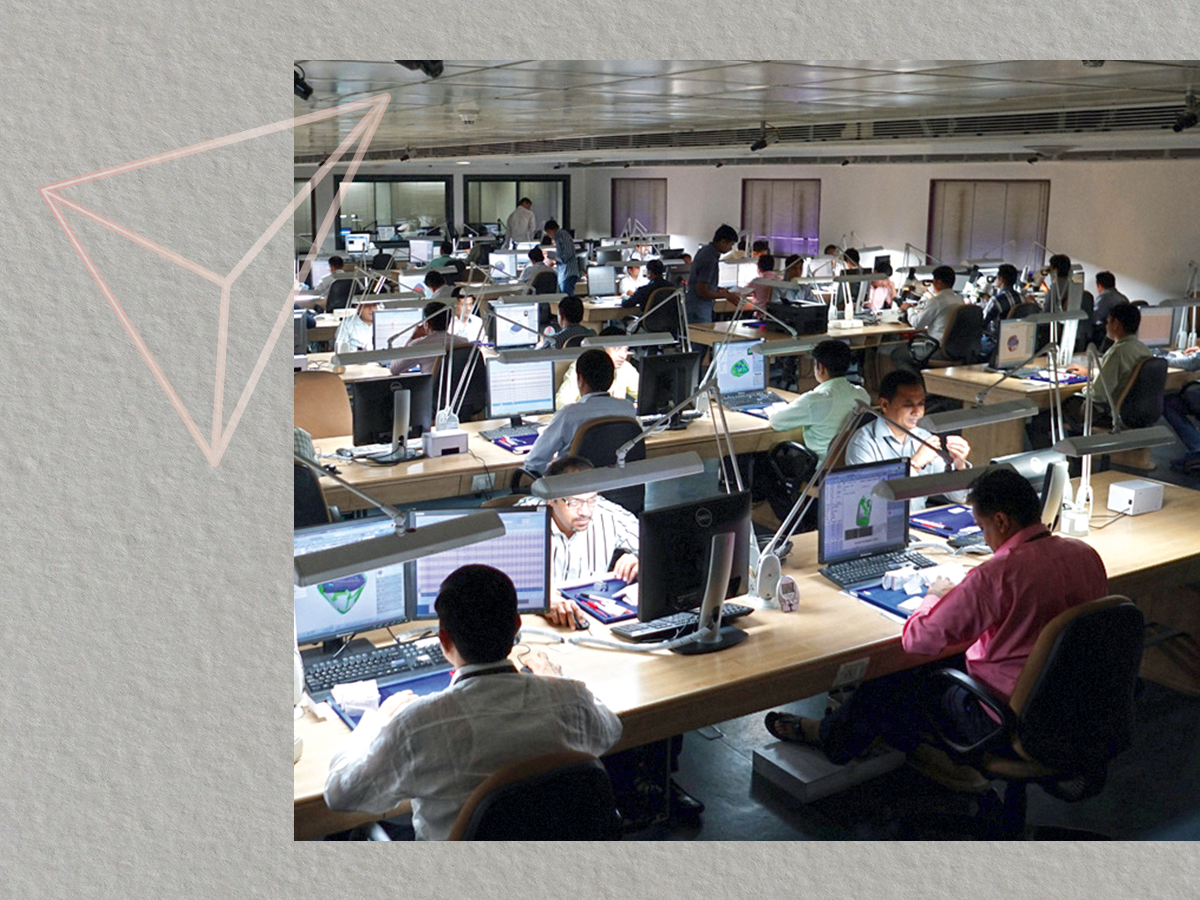

A low coordinated hum of diamond-cutting wheels is the first sound you hear when you enter any diamond cutting and polishing unit in the city of Surat. Skilled karigars sit in rows working on modern tools cutting and polishing diamonds to brilliant perfection. For these artisans, this is just another regular day at work. And yet, their job is like none other—years of training and practice have honed their skills to precision and every day, under their expert fingers, hundreds of uncut rocks are transformed into glittering, precious diamonds.

Rough diamonds from Europe, Africa and elsewhere arrive in Surat and are cut, polished and processed by local karigars. Thereafter, these precious gems find pride of place in jewellery houses and ateliers around the globe. It is in this port city that the world truly becomes local.

The Journey Of A Diamond

The majority of the world’s diamonds come from the mines of Africa, Russia and Canada. It is on the streets of Antwerp, Belgium that a mined diamond starts its journey and then travels onward to Surat where it becomes a sparkling finished stone.

The presence of a large Gujarati diaspora in this Belgian city and their leadership position in the diamond export business opened up the route between Antwerp and Surat. “Back in the day, going to Antwerp was considered a huge achievement. But family members of the Gujarati community helped one another get established there. Today, you can hear Gujarati over English or other European languages in the diamond hubs of Belgium,” says Dilipkumar Shah, Managing Director of the Surat-based jewellery brand BR Designs Pvt. Ltd. This, in turn, has led to a parallel growth of the business in Surat.

“When I learnt the craft in the 1970s, cutting used to happen on diamond-coated cement wheels. Today, one can find the most advanced machinery in Surat”

The Rise of Surat

Surat’s success as a diamond processing centre is remarkable considering its lineage is less than a century old. The British and Portuguese influence had already made this port city a vital trade route. Prevalence of gems, beads and pierced stones in the region developed an interest in diamonds as well. Government support, negligible competition and availability of unskilled and semi-skilled workforce from neighbouring states have also helped Surat grow. Its humble beginnings lie in a small-scale business set up in the early 1900s led by two enterprising brothers from Gujarat’s Patidar community, Gandabhai Kuberdas Mavjivanwala and Shri Rangeeldas Kuberdas Mavjivanwala.

Over the years, the industry expanded thanks to the efforts of several diamond merchants and exporters who set up units and developed teams who gradually developed great expertise in crafting high-value diamonds. Today, Surat lies at the heart of a thriving industry that boasts of an annual turnover of $24 billion. And a large part of this city’s magnificent growth story is the result of the hard work and craftsmanship of over 7,00,000 workers across 6,000 polishing units. Together, they process nearly 95% of the world’s diamonds. Surat’s startling success lies in its karigars, entrepreneurs, jewellers and their complete dedication to bringing the best out of each diamond.

Surat’s Diamonds: Traditions, Technology And The Way Ahead

Industriousness and family are the cornerstones of the Gujarati ethos and this forms the foundation of industries across the state. The diamond business in Surat is no different. Many manufacturing units have employees across three generations as well as their extended families and often operate like one large family.

In fact, the entire business model operates on this bond and an enduring trust. Till date, local courier men called angadias transport parcels of diamonds worth millions. Chittis, or an informal system of promissory notes, still mark transactions and are valued for generations. Timely deliveries and prompt payments are an integral part of the chain.

Another key to Surat’s success lies in its wonderful melding of tradition with craftsmanship and technology. Apart from upskilling workers and developing precision equipment for cutting and polishing, there has been a gradual move towards working with better stones. Entrepreneurs like Sevantibhai Shah, founder of Venus Jewel, had an important role to play in the process. His was the first Indian company to cut and polish large natural diamonds on a large scale paving the way for the country to become the world’s biggest diamond cutting and polishing centre. From mentoring his karigars in crafting high-value diamonds to strategic planning and managing risk during production, he changed the diamond processing sector in India.

The karigars of Surat also played a significant role in shaping the industry. Ramniklal Shah, co-founder of Venus Jewels, recalls, “We worked closely with our artisans and teams and went in-depth into various aspects to reinvent and redesign the most core operations of diamond cutting, thereby achieving greater efficiency, precision and the highest quality of finishing.”

“It wasn’t just about polishing diamonds with 56 facets for us, it was about proving that India could excel in this field as well.”

Other industry stalwarts like Govind Dholakia, Founder and Chairman at SRK Exports, also spearheaded a move towards empowering the workforce by regular training programmes, bringing in proper safety protocols and incentivising performance with financial rewards.

As a result of all these measures, Surat’s diamond karigars are now known the world over for their expertise in working with high-quality and large sized natural diamonds

Although diamonds from across the world travelled to Surat, once polished, they would find their way to other centres in India and abroad to be sold to different buyers. “Since the 1970s, all polished diamonds have been sold to traders in Mumbai’s Panchratna district. I used to travel to Mumbai three days a week initially. We used to sell directly to Indians as well as clients from China, Hong Kong, Bangkok and USA. The establishment of the Bharat Diamond Bourse in Mumbai helped make the process more formal,” says Dilipkumar Shah. However, Surat still lacked its own space to conduct these sales. This is poised to change as early as 2022 as the city is all set to get its own 6.6 million square feet diamond bourse. Soon all the diamonds processed in Surat will be sold in the city itself and this game-changing move will bring the world to Gujarat’s shores, writing yet another chapter in Surat’s globalisation stor

The Gujarati entrepreneur’s acumen that has made this city a diamond processing hub of the future has also given impetus to homegrown and international jewellery designers. The exceptional quality, finesse, immaculate craftsmanship, comparable pricing and ready availability of finest quality diamonds have made many global retailers look at Surat as the manufacturing hub for their diamond jewellery. Today, this city is the home base for many well-established Indian jewellery designers specialising in natural diamond ornaments.

Surat is a city where diamonds find a new lease of life. Crafted by nature over billions of years, in the hands of local karigars these rocks are shaped into precious gems and prized jewels. This city becomes the crucible where diamonds from mines around the world converge. Borders blend into the facets of a diamond. Surat is where a diamond of the world comes home.