A Jewelry Insider’s Journey to a Canadian Diamond Mine

The Diamonds Girl Tracey Ellison takes us on a trip of a lifetime to the Ekati diamond mine.

Every single day, for over eight years, multiple times a day, I’ve been posting images and videos on my social media accounts. And my near 7,000 posts all have a common denominator: they feature natural diamonds! And yet, until very recently, I had never visited the source where these rare gems are recovered from the earth. So you can only imagine my excitement when Only Natural Diamonds asked if I had an interest in visiting a mine… Well, yes, I think so!

Diamond mines are usually located in very remote places, and visiting one is an experience that even lifelong diamond professionals would not be lucky enough to have. To say I was excited would be an understatement. This lifelong dream of mine, it seems, would finally turn into a reality.

During Las Vegas Jewelry Week, I met with Clara Diamond Solutions, the technology arm of Lucara Diamonds and JDS Group of Companies, a leading mining contractor, to discuss a potential trip. The complexities of organizing a trip to such a remote area, and the number of people and companies that need to be involved cannot be overstated. Still, these boss ladies of the diamond business worked their magic and made it happen.

It was finally revealed that we would visit Canada’s Northwest Territories, a remote area way up in the north close to the Arctic Circle, where legendary diamond mines are nestled in a vast, empty landscape. We would be lucky enough to see the Ekati diamond mine, owned and operated by Arctic Canadian Diamond Company, and the Diavik Mine, owned and operated by Rio Tinto. These legendary mines were part of the beginning of diamond discovery in Canada in the early 90s.

Many people do not realize that Canada is the world’s third largest source of diamonds, boasting diamond exports, which in 2019, totaled $2.25 billion. Famous diamonds have been found there, too, like the 552.74 carat yellow diamond found at Rio Tinto’s Diavik mine in 2018.

Our trip began in Vancouver for dinner the night before we departed to the Northwest Territories, and it was there that I met Eira Thomas for the first time. An icon in the industry, Eira is not only CEO of Lucara Diamonds but, together with her father, Gren Thomas, is credited with leading the team that discovered Diavik, Canada’s second diamond mine. This trip would act as a homecoming for the two, as well as include my friends and fellow diamond fanatics, Sam Karmiel from IceRock Diamonds and Grant Mobley from the Natural Diamond Council. Another amazing woman and Co-Founder of Lucara, Catherine McLeod Selzer, also joined our dinner. Despite our jetlag and upcoming 7 a.m. flight, we had a wonderful evening, filled with anticipation for the following day.

The following morning, we were wheels up, comfortably in the JDS Group jet, heading to Yellowknife, the capital of the Northwest Territories. Yellowknife is a small remote city that has a population of just about twenty thousand and is popular for tourists hoping to see the Northern Lights. Though landing there was beautiful, we needed to transfer to a smaller plane that was able to land on the gravel runway a few hundred kilometers further north at the Ekati mine. This new plane was operated by Buffalo Airways, the company made famous by their History Channel reality show, Ice Pilots. The flight was incredible, with not one sign of humans for hundreds of miles in each direction, just a flat, treeless landscape pimpled with countless small lakes.

Finally… we arrived!

From when we arrived to when we left, Grant, Sam, and I were in a state of absolute amazement at all we saw. Despite our collective thirty-plus years of being in the diamond industry, nothing could prepare us for how complex and impressive a diamond mining operation is. We were warmly welcomed by Dr. Rory Moore, President, and CEO of Arctic Canadian Diamond Company (and a fellow South African!). He genuinely educated us about diamond recovery and gave us a tour of the whole operation.

The most profound observation was made by Grant, who said that after seeing all this, he couldn’t believe diamonds don’t cost a lot more!

The whole operation functions as a mini city. There is a full gym, basketball court, medical facilities, fire department and everything necessary to meet the needs of the nearly 1,000 employees working in such a remote area. Of course, the workers only work here for a couple of weeks at a time, alternating with a couple of weeks off, which is not a bad gig. We saw their workshops, where skilled engineers and mechanics work on the complex equipment and trucks that make a school bus look like a children’s toy. The sorting facility is where the magic happens. It is a complex network of equipment that takes the kimberlite ore found in the mine and, using only water and pressure, breaks it down into smaller pieces to find the rough diamonds hidden inside.

We took a helicopter to different mine areas to see the “pipes” where the kimberlite ore that contains diamonds is found. From the helicopter, you can awe at this incredible landscape, and though the mines seem huge from the ground, you get the sense they are such a tiny spec on an endless untouched landscape. We saw from above the beginnings of new operations that could have the ability to extend the life of the mine by years, positively impacting thousands of people.

It was clear that preserving the environment and minimizing the operational footprint are of utmost importance to the diamond mines. Understanding their respect for the land was one of my favorite learnings during this trip. The land is studied for months to establish animal migration patterns before mining to ensure there is no conflict. Land reclamation initiatives are ongoing, and inactive areas are restored to their pre-mining state. Eventually, when the mine is permanently closed, the companies will go to great lengths to restore the land to its natural habitat, with an estimated $30,000,000 set aside annually for land reclamation. Evidence of the commitment to the environment and its inhabitants was abundantly clear. We spotted a grizzly bear roaming free, a mama wolf with four cubs and foxes—to name a few. They ensure that absolutely nothing is allowed to disturb any animal’s natural activity, stopping the operation if needed.

The most beautiful thing to see was no doubt the pride that the local people and other workers have for what they do and pride for the diamonds coming from their homes and the lasting effect their discovery has had on the area. Arctic Canadian and Rio Tinto are focused on their community impact, providing apprenticeship programs, leadership development programs, employing locals and indigenous groups, and everything they can to keep the benefits substantial and local.

Before this trip, I knew little about the Canadian diamond industry. Being South African, I was always a little snobbish about Southern African diamonds being the best in the world, But I am pleased to say that assumptions have been challenged and laid to rest. Canadian diamonds are produced under one of the world’s most stringent, transparent and environmentally responsible regulatory systems. Initiatives launched by the Mining Association of Canada (MAC) mean you can buy Canadian diamonds knowing they are above and beyond conflict-free, positively impacting the people and area where they are found.

Elated and on a high, we boarded our Buffalo Air flight back to Yellowknife to join many locals, OG explorers, miners and diamantaires for dinner and then on to a local bar to enjoy live music and dancing. It was a superb way to end a magical and long day, especially as the sun doesn’t set.

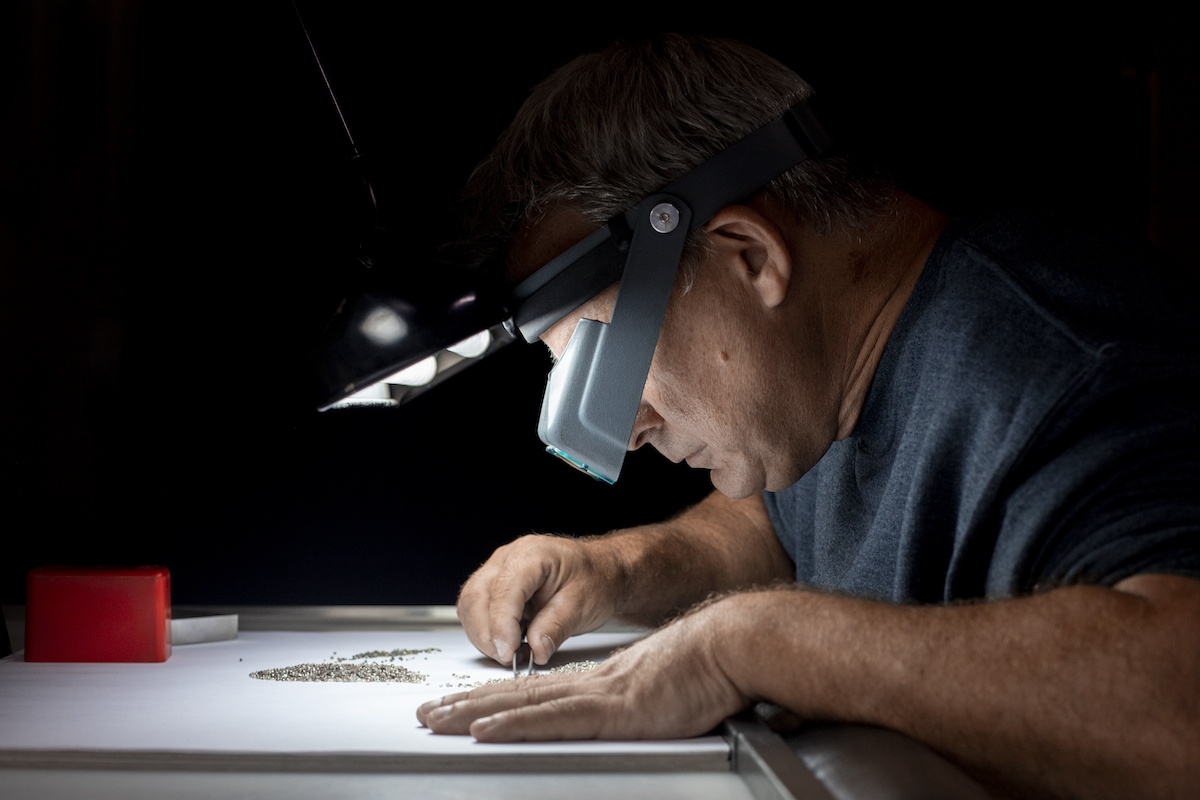

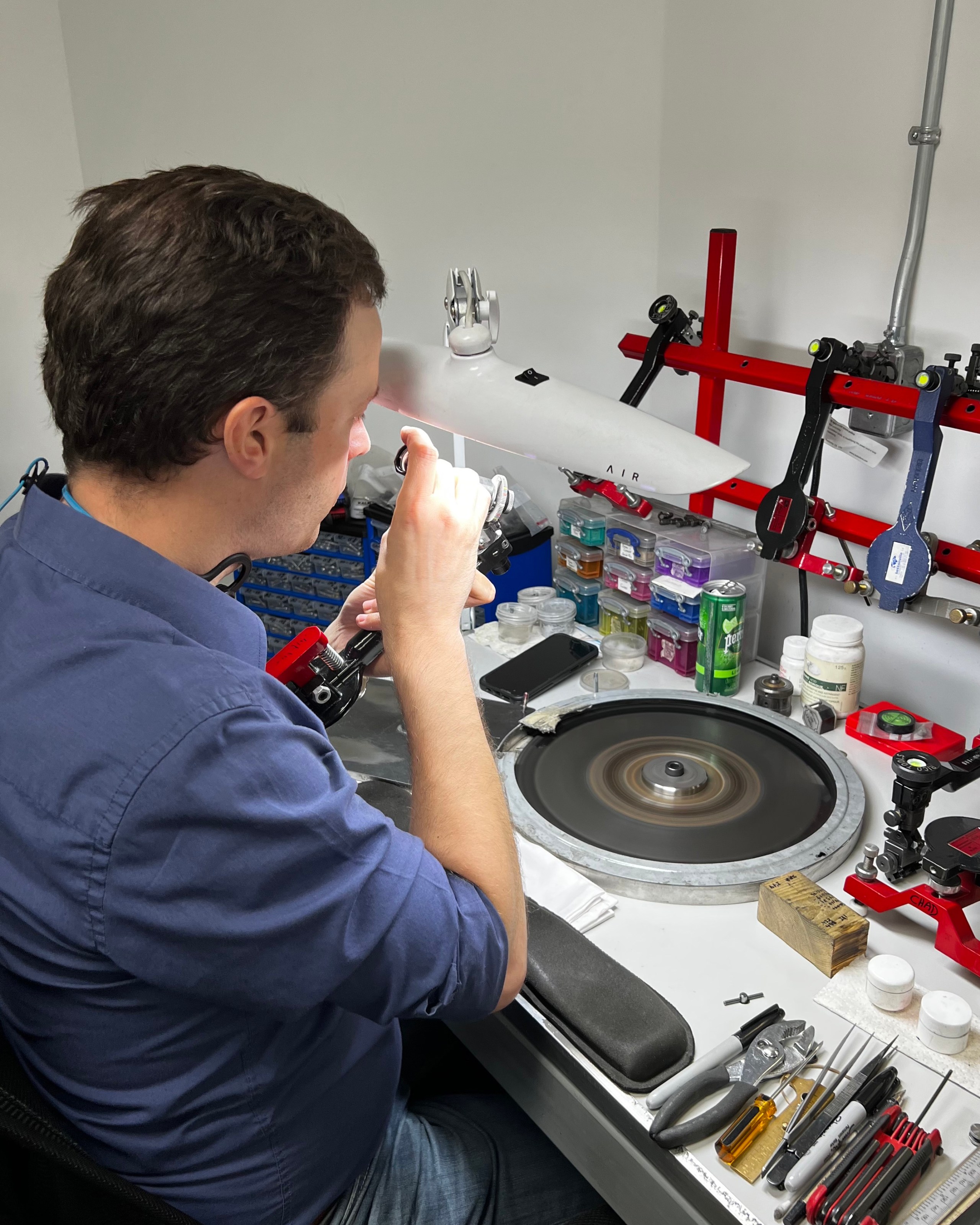

The following day, we woke bright and early and visited Diamonds de Canada, a cutting and polishing operation in Yellowknife that cuts diamonds found in the area. Their facility employs locals from the area and indigenous people, teaching them the art of diamond cutting while keeping the benefits local. Diamonds de Canada was awarded the exclusive right to bring back the iconic Polar Bear diamond trademark. It will be used only for diamonds found in one of the NWT’s three mines and cut and polished there.

From there, we visited the NWT Diamond and Jewellery Centre, a diamond museum dedicated to the Northwest Territories with the bonus of being a jewelry store.

Sadly, it was time to fly back to Vancouver and leave the NWT behind. A whirlwind of 48 hours has left an everlasting impression on everyone who had the honor of visiting this incredible part of our world and the privilege of meeting so many amazing people.